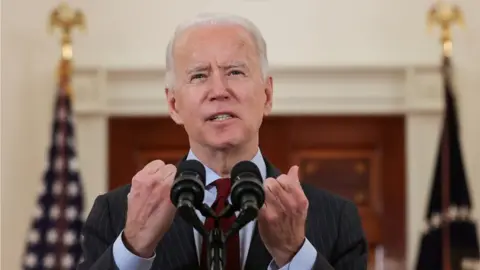

Biden orders 100-day review amid supply chain strains

Reuters

ReutersUS President Joe Biden has ordered officials to find ways to bolster supply chains as a shortage of computer chips hits carmakers around the world.

It comes after the pandemic has strained many producers and forced the US to scramble for medical gear.

The initial review is focused on computer chips, pharmaceuticals, rare earth minerals and large batteries, such as those used in electric cars.

China is a key supplier for many of those items.

US officials said the review was not targeted at China, which like the US imports most of its computer chips and has been trying to boost domestic production.

They said the administration was interested in increasing some production in the US and expected to work with other countries for items that could not be made domestically.

Reliance on "strategic competitor nations" is expected to be part of the analysis, they added.

Getty Images

Getty Images"While we cannot predict what crisis will hit us, we should have the capacity to respond quickly in the face of challenges," the White House said in a statement announcing the study, which will start with a 100-day focused review, before widening its scope.

"The United States must ensure that production shortages, trade disruptions, natural disasters and potential actions by foreign competitors and adversaries never leave the United States vulnerable again."

Under pressure

The president, who will formally sign the executive order on Wednesday, has come under pressure as firms such as General Motors and Ford have cut production and announced lay-offs due to the shortage of chips - key components for many electronic products, which have been in high demand due to the pandemic.

Republicans have also pushed Mr Biden to do more to address reliance on China, while business and technology lobby groups have also called on the administration to introduce investment tax credits to encourage the building of more US semiconductor manufacturing plants, where the chips are produced.

"While the governments of our global competitors have invested heavily to attract new semiconductor manufacturing and research facilities, the absence of US incentives has made our country uncompetitive and America's share of global semiconductor manufacturing has steadily declined," the groups wrote in a recent letter, signed by the US Chamber of Commerce, the Semiconductor Industry Association and the Alliance for Automotive Innovation, among others.

"To be competitive and strengthen the resilience of critical supply chains, we believe the US needs to incentivize the construction of new and modernized semiconductor manufacturing facilities and invest in research capabilities."

US semiconductor firms currently account for 47% of global chip sales, according to the Semiconductor Industry Association. However, just 12% of chips are made in the US, down from 37% in 1990.

Under former President Donald Trump, the US adopted a protectionist approach, increasing border taxes and in some cases forbidding US firms from doing business with Chinese competitors in an effort to boost US producers.

Amid the changes, Taiwan Semiconductor Manufacturing Co. (TSMC), the world's largest contract chipmaker, last May announced plans to build a $12bn (£8.5bn) factory in the US.