Why astronauts are printing organs in space

Nasa

NasaWith a global shortage of organs suitable for transplant into critically ill patients, some researchers are looking at 3D printing of living tissue as a solution – but to do it they might need to go into orbit.

Andrew Morgan has seen some of the worst things that can happen to the human body. As a battlefield doctor with the US Army, he's treated young soldiers whose bodies had been torn and broken in explosions. "I've seen the loss of limbs and some devastating injuries as the result of blasts," he says. Witnessing the slow healing and recovery process first-hand got Morgan thinking – what if new tissue or even entire organs could be simply printed off to replace injured body parts?

"The ability to transplant tissues made from the injured person's own cells would be hugely beneficial," he says.

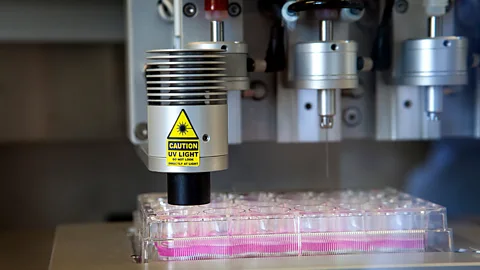

That's why Morgan conducted a series of unusual experiments over several months last year – in outer space. You see, Morgan is also a Nasa astronaut. In April 2020 he returned from a 272-day stay on the International Space Station (ISS). While he orbited 248 miles (400km) above the Earth's surface, Morgan created living tissue, cell by cell, using a 3D printer and something called bio-ink.

"It's not unlike changing a printer cartridge at home," says Morgan of the equipment he used. "You put in the ink cartridge, allow the culture to develop and then remove the tissue cassette for analysis."

So far, so simple. But there is a reason why Morgan and his fellow astronaut Christina Koch were doing these experiments while in orbit.

"When you're 3D-printing a tissue culture on the ground, there's a tendency for them to collapse in the presence of gravity," he says. "The tissues require some sort of [temporary, organic] scaffold to hold everything in place, especially with cavities like the chambers of a heart. But you don't have those effects in a micro-gravity environment, which is why these experiments have been so valuable."

Nasa

NasaThe micro-gravity environment of the ISS was ideal for testing the Bio Fabrication Facility, which was launched into orbit in 2019 and is due for an upgrade in 2021. Developed by US companies Techshot and NScrypt, it is designed to print human cells into organ-shaped tissues. Initially Morgan was using it to test prints of cardiac-like tissue of increasing thicknesses. Ultimately, however, the team behind the technology hopes to refine the equipment so they can print entire human organs in space, which can be used in transplants.

Printing human organs is not quite as science fiction as it sounds. A number of bio-technology companies are working on different approaches, which aim to use a patient's own cells make new tissue. In most cases they re-programme the cells by following a Nobel Prize-winning process developed a decade ago to turn them into stem cells, which are then theoretically capable of developing into any part of the human anatomy. Given the right nutrients and encouragement, these can then be induced into the cell type of choice. By suspending stem cells in a hydrogel that can be built into a scaffold to stop the growing structure collapsing in on itself, the desired cell type can then be printed layer by layer into living, functioning tissue.

"We've already produced tissue that has successfully been transplanted back onto animals – skin transplants, for example," explains Itedale Redwan, the scientific officer for Cellink, the first company to commercialise bio-ink. "Recently we've worked on laser-assisted printing to allow printing at the very small level of capillaries, or blood and waste transplant vessels. Being able to print at this level will be essential, but the big step will be putting such tissue into humans."

Redwan estimates it could be 10-15 years before fully functioning tissues and organs printed in this way will be transplanted into humans. Scientists have already shown it is possible to print basic tissues and even mini-organs. In 2018, a team at the University of Newcastle printed the first human corneas, while a group at Tel Aviv University produced a miniature heart by printing with human tissue from a cardiac patient and believe it could be used to engineer cardiac patches to repair heart defects. Scientists at Michigan State University have since taken that a step further by printing a mini human heart using a stem cell framework that imitates the environment in which a foetus develops, allowing for the creation of all the cell types and intricate structures necessary for a functioning heart.

But the heart is a relatively simple pump consisting of a series of chambers surrounded by muscle tissue. Some researchers have already made headway towards building more complex organ and tissue structures. One group at Wake Forest Institute for Regenerative Medicine in Winston-Salem, North Carolina, have integrated nerve cells into printed muscles, a key step towards restoring muscle control and function in future transplants.

Building full scale, complex organs like the liver and kidney, however, is a far bigger challenge. These organs are mixtures of many cell types, infused with networks of blood vessels and nerves.

You might also like:

Jennifer Lewis, a professor of biologically inspired engineering at Harvard University who has experimented with tissue printing, takes a cautious view on the hurdles still to overcome. Recreating the full function of an organ – the synchronicity of the heart's action, for example, or the filtration function of a kidney – is no easy thing. An important step will be replicating the process of organogenesis – where the multi-cellular architecture of human tissue and organs form in the embryo to develop different functions, she says.

"We're finding, for example, that often the function of tissue is not as mature when created in the lab as opposed to in vivo," says Lewis. "They might do this kind of thing on Westworld easily enough, but that's the dream. Yet you can see the pathways to how that might become a reality within a couple of decades."

BSIP/Getty Images

BSIP/Getty ImagesOne company, BioLife4D, which develops and manufactures bio-printing technology, is focusing on printing biological components for use in repairing the human heart as stepping stones towards producing an entire printed transplantable heart. It believes there's a multi-million dollar market for the various components, such as heart valves, that it will need to learn how to print along the way.

"But if you're able to print a liver, you have nothing until you print the next entire liver," says the company's chief executive Steve Morris. "From a scientific standpoint you could also bio-engineer a heart with a specific defect to allow for the testing of treatment."

Redwan stresses that, in the short term, printed organs will make it possible to more effectively model diseases in the laboratory and aid drug development. That, in turn, should help to decrease levels of animal testing. In the medium term, when full-sized organs are printable, the challenge may then become meeting demand. Currently there are huge shortages of donor organs to meet demand for those who need a transplant.

"There are, for example, around one million people around the world waiting for a kidney transplant," says Lewis. The World Health Organization estimates around 130,000 organ transplants take place each year, but this meets just 10% of the transplant need. In the US alone there are 107,000 patients on transplant waiting lists. "Just to be able to offer those people organs would be of huge impact in and of itself," says Lewis.

Those lucky enough to receive a donor transplant also have to spend the rest of their lives on immunosuppressant drugs to stop their bodies rejecting these "foreign" organs. But if a new organ can be printed using their own cells, it should greatly reduce the risk of rejection.

Faced with such need and potential benefit, it makes the great lengths needed to grow organs in space seem more worthwhile. But printing in space doesn't come cheap. The Bio Fabrication Facility on the ISS cost $7m (£5m), and add to that the cost of firing the cells and other raw materials into orbit before bringing the organs back safely. Large production runs are also going to be difficult. It has led some to investigate whether the low-gravity environment found in orbit can be replicated back here on Earth to grow complex, delicate organs. Russian medical company 3D Bioprinting Solutions, for example, has produced a system that uses a magnetic field to levitate tissue as it forms the desired structure.

Scientists also have to work out how to get a printed organ's vasculature and nerve endings to work. But in the meantime it's expected that the Bio Fabrication Facility might be able to take on work for industrial and institutional customers looking to explore its potential for printing tissue further. Some such as Techshot's chief scientist Gene Boland imagine a time – in the 2030s or 2040s perhaps – when bio-print facilities are established in low Earth orbit, taking advantage of the micro-gravity environment to print ever more complex human tissues to, perhaps, ever more advanced specifications.

For others trying to develop this revolution in transplant technology, the quest is deeply personal.

"My daughter was born with only one lung," says Ken Church, chief executive of NScrypt, the company that helped to develop the bio-printer used by Andrew Morgan on the ISS. "She's 27 and fine now but still only has one lung. But that got me looking into subject of tissue engineering – back when bio-printing wasn't a thing – and I became fascinated by the idea of it."

NScrypt is now developing the next generation bio-printer, a bio-reactor, which, rather than benefitting from a low-gravity environment to prevent necrosis at the centre of any printed tissue, does so with other approaches, such as spinning it, shaking it, or infusing it with oxygen as it grows.

"If I can grow a lung for my daughter in her lifetime, that excites me," says Church.

But while it is easy to get caught up in the excitement of printing organs on demand, there are also some other, bigger implications that require thought. The prospect of being able to print human organs is, after all, likely to have a profound impact on society, not least in the boost to average longevity that it entails. If cardiovascular disease is the leading cause of death for most people in the West – an estimated one in three people die from it – replacing the heart with a younger, healthier one, could potentially add decades to lifespans. Not everyone, it seems, is happy with that idea.

Yuri Kadobnov/Getty Images

Yuri Kadobnov/Getty Images"We've had complaints, with one email calling us 'evil incarnate'," says BioLife4D's Morris. "They argued that the ability to print organs and so extend life wasn't right given the scarcity of resources already leading to so much suffering and that extending lives would only extend that suffering."

There are other potential ethical tightropes to be walked too.

"What if some parent requests that their 12-year-old's heart is replaced with a bigger one so that it pumps harder, with greater efficiency, and so he becomes the star athlete at school," he suggests. "If we can print a heart with two valves, why not print one with an extra two valves built in? Personally, I have doubts here – if evolution hasn't already given us a heart with extra valves we probably shouldn't go there. But if you had to replace an organ anyway, I wouldn't have aversions to replacing it with one that's in some way improved."

Faced with the high cost of printing organs – particularly if they are grown in orbit – delivering hearts or lungs that have been enhanced in some way could be a way of attracting people who are willing to pay for these techniques.

"This is going to be a very divisive question," says Ravi Birla, a tissue engineer with BioLife4D. "If you change everything in a person, organ by organ, arguably what's left isn't the human that was born, but some other creature."

He says while at the moment the focus is on using organs for life-saving surgery, there will inevitably be some comparisons with cosmetic surgery too. "The question now is how one draws the boundaries between the two," he says. "And it's easy to see how one might see the option for enhanced organs as akin to the use of performance-enhancing drugs in sport – most people may be against them, but they're still used, still they're commercialised."

But perhaps the most dramatic uses of organ printing will not be here on Earth at all. As humans start delving deeper into space by first returning to the Moon and then beyond to Mars, bio-printing could be an essential, life-sustaining tool. Millions of miles from Earth, organ donors will be in short supply, but so too will something else – food.

"This is the tip of the spear as to the possibilities of printing organs," says Boland. Techshot, which part-funded the installation of the bio printer on the ISS and oversaw some of the remote operating experiments, assisted by astronaut Andrew Morgan. The company has now signed an agreement with space station company Axiom Space to install the first commercial bio-printer on the ISS too.

"Eventually bio-printing is going to be important for deep space exploration too – for the printing of animal cells for food, or of tissues in the case of medical emergencies.

"In the meantime these experiments on the ISS are going to unlock some of the secrets of bio-printing to make it work here on Earth first. This is the real leapfrog moment."

--

If you liked this story, sign up for the weekly bbc.com features newsletter, called "The Essential List". A handpicked selection of stories from BBC Future, Culture, Worklife, and Travel, delivered to your inbox every Friday.