Can we make fashion greener?

MIGUEL MEDINA

MIGUEL MEDINAWe continue to buy new clothes at an incredible rate. How can manufacturers reduce fashion's environmental footprint?

According to the Valuing Our Clothes report analysing the contents of British wardrobes by the Waste Resources Action Programme (WRAP), we purchased 1,130,000 tonnes of new clothing last year in the UK.

Meanwhile, an estimated £30bn worth of our clothing hangs about gathering dust because we simply don't have time to wear it all or don't really like what we're buying.

This is the epoch of "fast fashion" - a rapid production system that promises quick turnaround of trends and low prices, with a supply chain that snakes through some of the lowest wage economies on Earth.

Fast fashion brands dominate not just high streets, but our wardrobes and represent the three trillion dollar global fashion industry's greatest success story. But at what cost?

The environmental footprint of today's fashion industry is extraordinary, making it one of the top five most polluting industries on earth, alongside the petrochemical industry.

Many fashion industry insiders are seriously worried, not necessarily because they fret over greenhouse gases caused by the supply chain, but because there is now so much over-supply of fashion that it's becoming difficult to have a successful season - particularly as we now have 50 seasons rather than the traditional two of spring/summer and autumn/winter.

Some commentators refer to today's relentless cycle as a "supermarket of style".

Cause for optimism?

But according to fashion theory, there are 101 steps to producing a garment from processes such as dyeing and finishing to pressing the garment ready for retail.

If you're a pessimist that's 101 chances to introduce pollution, exploitation and planetary degradation. If however you're an optimist, that's 101 opportunities to take the impact out of fashion!

So for a new episode of BBC Radio 4's Costing the Earth, I travelled to Milan Fashion week to meet some disruptors (and definitely optimists) who believe we are on the cusp of a green revolution that can turn the industry around.

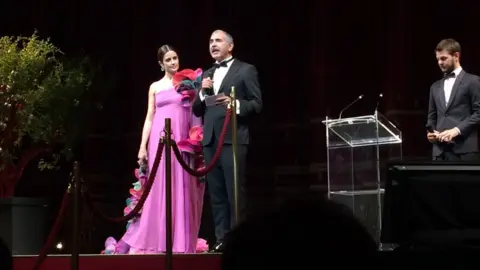

At the Green Carpet Fashion Awards Italia, that took place at the famous La Scala opera theatre during Milan Fashion Week it was difficult not to be blinded by the super star wattage pacing the deliberately "green" carpet (manufactured from old fishing nets and carpets).

Anne-Marie Bullock

Anne-Marie Bullock Eco Age

Eco AgeBut among the stars - Gisele Bundchen, Naomi Campbell, Colin Firth, Giorgio Armani were all in attendance - were a number of eco innovation show stoppers.

One model wore an eye catching dress made from apple leather and creating by emerging designer, Matje Benedetti who explained how waste apple pulp from the apple industry is mixed with polyurethane to develop the fibre.

The inclusion of ecological innovative fibres at this level - awards on the night also went to Orange Fibre, a company spinning yarn from citrus waste - points to serious investment in revolutionary new materials.

Silky skills

Case and point is provided by New York biotech start-up Modern Meadows. Here biologists work alongside creative director, Suzanne Lee and fermentation engineers to bio-fabricate leather in the laboratory.

This research and development promises a future where cows will not be required for a handbag and where fashion design intersects with biology.

Getty Images

Getty ImagesMeanwhile, Californian start up Bolt Threads has raised millions of dollars to bring its brewed spider silk to market (Stella McCartney has designed with the material) and fashion entrepreneur Miroslava Duma recently launched a $50 million fund and accelerator dedicated to bringing new sustainable fibres and fabrics to market.

In many ways this fibre revolution is long overdue. The fashion industry, for all its claims of being cutting edge, is remarkably conservative when it comes to fabrics. Humanity is almost exclusive clothed in polyester and cotton fibres, both of which have shocking environmental profiles.

This also means that the last significant innovation in materials was polyester, circa 1943!

3D printing

But what we're also seeing here are levels of and investment in disruptive technology and innovation that have previously been applied to the technology and transport sector, applied to fashion. This is potentially a game changer.

However, we do still need to address the issue of our own over consumption, an area where we've made little headway.

But there's innovation here too: designer Danit Peleg 3D prints her collections and thinks in the foreseeable future we will be able to effectively design out shopping for fashion by 3D printing to order.

It's another innovation to get excited by and a disruption that could represent an enormous gift to the biosphere given the impact of our consumption. But I'd have to concede it's early days for all of this innovation.

Reuters

ReutersSo amid such headline-grabbing, tech-fuelled disruption is there a more immediate, human, low-tech answer right in front of us?

Psychologist Professor Carolyn Mair has observed that we're inclined to keep stuff circulating in our wardrobe to which we've attached a strong personal narrative.

Mair told me about her favourite example: "a pair of lucky pants". Many people secretly own a pair to which they attach talismanic significance and they have huge longevity!

Behaviours like these can turn fashion green. WRAP research shows that extending the life of clothes by an extra nine months of active use, in the UK, reduces the carbon, water and waste impacts of that garment by around 20-30%.

Standby then for a wardrobe future where you'll be able to access cutting edge bio-fabricated novel material that's been 3D printed in a pair of very lucky pants. That's what I call fashion forward.

Costing the Earth is available now and on BBC Radio 4 on Thursday 11th Oct at 9pm