UK energy plant to use liquid air

Highview

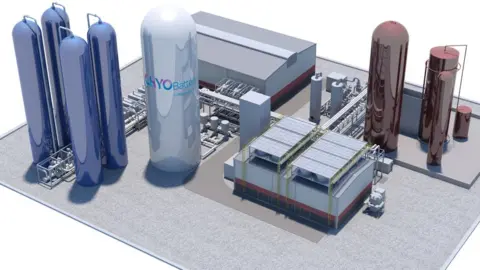

HighviewWork is beginning on what is thought to be the world's first major plant to store energy in the form of liquid air.

It will use surplus electricity from wind farms at night to compress air so hard that it becomes a liquid at -196 Celsius.

Then when there is a peak in demand in a day or a month, the liquid air will be warmed so it expands.

The resulting rush of air will drive a turbine to make electricity, which can be sold back to the grid.

The 50MW facility near Manchester will store enough power for roughly 50,000 homes for five hours.

The system was devised by Peter Dearman, a self-taught backyard inventor from Hertfordshire, and it has been taken to commercial scale with a £10m grant from the UK government.

"It's very exciting," he told BBC News. "We need many different forms of energy storage - and I'm confident liquid air will be one of them."

PA

PAMr Dearman said his invention was 60-70% efficient, depending how it is used.

That is less efficient than batteries, but he said the advantage of liquid air is the low cost of the storage tanks - so it can easily be scaled up.

Also, unlike batteries, liquid air storage does not create a demand for minerals which may become increasingly scarce as the world moves towards power systems based on variable renewable electricity.

"Batteries are really great for short-term storage," Mr Dearman said. "But they are too expensive to do long-term energy storage. That's where liquid air comes in."

Mr Dearman had been developing a car run on similar principles with liquid hydrogen when he saw the potential for applying the technology to electricity storage.

He is now a passive shareholder in Highview, one of the firms building the 50MW plant.

Prof John Loughhead, from the government's business and energy department, has previously praised the technology.

Follow Roger on Twitter @rharrabin