Apple iPhone X: The network of suppliers set to benefit

Getty Images

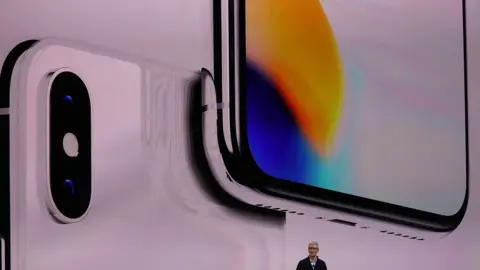

Getty ImagesAs consumers consider whether to spend big on the new $999 iPhone X, Apple isn't the only company hoping for a sales boost.

A global chain of components and technology suppliers are used to build Apple's smartphones.

The tech giant has designed certain parts of the X's internal components.

But new features such as 3D facial recognition and an expansion of augmented reality functions will boost specialised suppliers.

The iPhone X, a glass and stainless steel device with an edge-to-edge display, was unveiled in the US on Tuesday.

Component mix

Like previous models, the new phone, Apple's most expensive yet, will be made up of parts from around the world.

Until analysts crack it open and examine the inner workings of the device, it's not clear exactly which suppliers will be the biggest winners in the provision of parts such as batteries, memory chips and screen displays.

But the past gives a good guide.

Jake Saunders, Asia-Pacific vice president for ABI Research, in Singapore, said Apple was unlikely to depart too much from its iPhone 7 supplier base.

For that model, Mr Saunders said Intel, which provides the modem that handles data traffic, was the biggest third-party supplier.

He said Intel parts made up around 15% of the value of the device.

Other big contributors were Japan's Toshiba, US firms Broadcom and Texas Instruments, and the UK's Dialog Semiconductor.

Getty Images

Getty ImagesThose firms are likely to feature again, but another name to watch is Lumentum.

The US company, which makes components of 3D sensors, may benefit from the phone's new facial recognition technology.

Lumentum said it has received $200m (£150m) in orders for these lasers since April. The company said it has various customers, but many analysts believe that orders from Apple are behind the sales surge.

Samsung stands to take cut from the OLED display screens - which do away with traditional LCD backlight technology - it is supplying for the new phone.

Canalys research analyst TuanAnh Nguyen says the South Korean conglomerate, which controls roughly 90% of the OLED display market, is poised to be a big winner of the iPhone X.

Taking control

However, some suppliers will be squeezed as Apple moves to design more of the iPhone's internal components.

The latest phones feature Apple's first proprietary graphics processor, which provides more speed, improved cameras and some features for augmented reality apps.

The iPhone maker had previously used graphics chips from Imagination Technologies Group, which put itself up for sale earlier this year after Apple said it would make its own technology.

Getty Images

Getty ImagesMore opportunities

Despite Apple's shift away from graphics chips suppliers, other firms are poised to benefit as the iPhone maker deepens its augmented reality (AR) functions in future devices.

Canalys analyst Mr Nguyen said the focus on AR - think functions like Pokemon Go - could pay fresh dividends for some partner firms.

"There are more opportunities for new suppliers who focus on products such as light sensors, light receivers, and cameras because Apple is committed to a future where the camera offers AR experiences," he said.

Assembly line

To put all the parts together, Apple's handsets are assembled in China. The country is home to the biggest iPhone factory in the world, run by Taiwanese manufacturing partner Foxconn.

Apple is also looking to India. Earlier this year the firm said it will start making iPhones in the southern Indian state of Karnataka.

That could change the part mix - for it to be able to sell direct to customers in India, Apple would have to source 30% of the components of its products locally.