Work to assemble huge pre-fab HS2 viaduct begins

HS2 Ltd

HS2 LtdWork is under way to assemble a 515m (563 yard) viaduct for the HS2 project from sections made off site.

The structure in Edgcote, Northamptonshire, is the second viaduct to have every major element manufactured elsewhere.

HS2 Ltd said the technique reduced the project's carbon footprint and simplified construction.

The viaduct will carry the new railway over the River Cherwell flood-plain.

HS2 was originally designed to facilitate high-speed rail journeys between London and northern England, but the high cost resulted in the previous Conservative government scrapping the route north of Birmingham.

The newly-elected Labour administration made it clear in the King's Speech that it did not intend to reinstate the section between Birmingham and Manchester.

Construction continues, however, on the London to Birmingham phase, that will feature more than 50 major viaducts.

HS2 Ltd

HS2 LtdThe original design for the Edgcote Viaduct involved five beams per span, secured with concrete poured on site.

It was redesigned last year - copying the method used at the Thame Valley viaduct near Aylesbury - meaning it will have just two larger U-shaped beams on each span, secured to neighbouring beams.

HS2 Ltd said this technique was "inspired by viaducts on the Spanish high speed rail network [and] will reduce the number of lorry movements and speed up construction by removing the in-situ concrete work".

HS2 Ltd

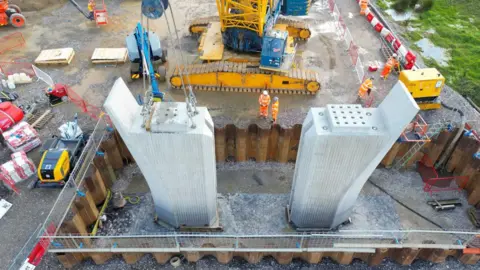

HS2 LtdThe viaduct, which will vary in height from six to eight metres (20ft to 26ft), will be supported by 20 pairs of pre-cast concrete piers.

These will be lifted into position with steel reinforcing rods being slotted into pre-prepared sleeves.

Two new wildlife sites will be created where the viaduct crosses the flood-plain to attract insects, bats and newts.

HS2 Ltd

HS2 LtdSuhel Uddin, HS2 Ltd's senior project manager, said: "It's great to see the first piers in place for Edgcote viaduct after our structural redesign.

"The success of the Thame Valley viaduct design shows that a two-beam approach can bring significant benefits for viaducts of this length – speeding up construction, boosting efficiency and improving safety on site by reducing the amount of working at height."

There was concern that the viaduct would pass close to the site of the 1469 Battle of Edgcote, but HS2 Ltd said "archaeological investigation has not found any evidence of the battle at the viaduct construction site".

Follow Northamptonshire news on BBC Sounds, Facebook, Instagram and X.