Researchers 'crack code' to perfect biscuit crunch

University of Warwick

University of WarwickWarwick University has partnered with a confectionery firm to uncover how to bake the perfect biscuit by using X-ray equipment.

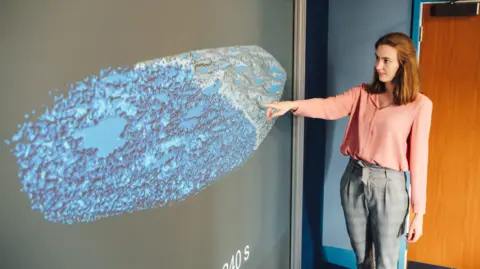

Researchers scanned biscuits in a bespoke oven to analyse their structure and find how the "perfect crunch" forms.

The team at the University of Warwick built the oven inside an X-ray CT scanner – similar to machines used in hospitals.

An imaging process was used to scan the biscuit every 20 seconds throughout the baking process.

Jay Warnett, associate professor at Warwick Manufacturing Group's (WMG) Centre for Imaging, Metrology and Additive Technologies, said: "We're cracking the code to the perfect biscuit.

"Through our X-rays, we're helping uncover the ideal baking time, thickness, and recipe for the ultimate eating experience”.

The research process was led by Dr Warnett and research fellow Dr Evelien Zwanenburg. The experiment was the first step before a larger project later this year, said the university.

Researchers took images of the inside of the biscuit to reveal how the porous structure, essential for the perfect ‘crunch’, forms during the baking process.

An oven was constructed from scratch inside a scanner, and algorithms were used to speed up the imaging process.

The biscuit was scanned every 20 seconds throughout the baking process. When put together, the WMG and Cadbury teams could observe the biscuit baking over time.

Principal scientist at Cadbury, Thomas Curwen, said he was excited for the future of biscuit development.

He said: "The latest algorithms have allowed us to watch and quantify the baking process inside the biscuit in greater detail than ever before.

"This capability will help us determine the function of different ingredients in more detail and how the structure that forms controls the eating experience.

"I am excited by what we can learn and how this will help us deliver the great-tasting biscuits of the future.”