Champagne stoppers in space: How cork will protect the next spacecraft to visit the Moon

Nasa

NasaWhen you think of cork, you might think of that pop of champagne on New Year's Eve – but some of this versatile tree bark will also be keeping astronauts safe as humanity returns to the Moon.

The space age has brought the world many cutting-edge gadgets and innovative new materials – from super-strong alloys and memory foam to freeze dried foods and the sensors in your mobile phone camera. Advanced technologies such as these have helped Nasa and its fellow space agencies push ever further into the vastness of outer space. So, it might be something of a surprise to see the next era of space exploration relying on a much humbler substance as humans aim to return to the Moon and even beyond to Mars – cork.

This ancient material – which is harvested from the bark of trees that grow around the Mediterranean – is probably most familiar as stoppers in wine and champagne bottles. But its extraordinary properties has seen it used in crucial bits of space rocket hardware and it could come to play an even greater role in years to come.

The world is currently witnessing an "exponential" growth in space travel as commercial space companies make firing satellites, spacecraft and even people into orbit ever cheaper. But rocket launches can take a considerable toll on the environment, so scientists and space agencies are hoping to find ways of making space flight more sustainable. Many are looking to natural materials as a way of minimising their impact on the Earth and beyond.

But are trees really up to the extremes of space? And what does sustainability actually mean to the aerospace industry?

Corticeira Amorim

Corticeira AmorimMaterials that can withstand the extremes of space travel must be able to multitask. They need to be lightweight but also super strong, temperature and radiation resistant – and even capable of transforming in response to their environment. That's why researchers are experimenting with emerging materials with unusual properties. But they are also reverting to some that have been used by humans for thousands of years.

How is cork harvested?

The cork oak tree is an unusual crop – it can be "harvested" without cutting it down as only the outer bark is removed. A cork oak tree can live for up to 200 years and be harvested around 16 times during its lifetime, without causing lasting damage to the tree. This means the trees can live out their full lives, serving as long-lasting carbon sinks. Cork forests have also been found to prevent desertification and provide habitat for a huge number of animal and plant species, boosting biodiversity. (Read more about why cork is making a comeback in this feature by Alistair Leithhead.)

Grown mainly in southern Mediterranean countries, cork has been used by humankind for 5,000 years. In recent decades, it's been used in a multitude of applications from refrigerators to polar research ships and submarines.

"The cork forest is a unique ecosystem," says Antonio Rios Amorim, chief executive of Portuguese cork producers Corticeira Amorim. "It is one of the world's 36 biodiversity hotspots. It contributes to climate regulation, is a driving force for sustainable development and plays a crucial role in the world's ecological balance."

Corticeira Amorim has been producing cork for more than 150 years, and has been supplying the aerospace industry since the 1960s.

"70% of the cellular structure of cork is air," says Amorim. "For every cubic centimetre you have 40 million cells. This means it's a very light material, and it has extremely strong cell walls. This makes it a very good insulator." Cork, he adds, can withstand extreme temperature changes. "This is not done by us, this is a gift from nature."

In the 1960s, sheet cork was used to insulate the Minuteman Missiles, the American long-range missiles designed to carry thermonuclear warheads during the Cold War. Boeing used cork mixed with resin in their expendable launch system, Delta IV, due to its anti-charring properties. In 2020, the European Space Agency (Esa), also tested cork as an insulator for re-entry when the Qarman satellite was dropped from the International Space Station, gathering data on atmospheric re-entry as it fell back to Earth. And cork is currently used in United Launch Alliance's Atlas V, the main launch vehicle used by Nasa over the past 21 years that has carried robotic missions to Mars and Jupiter.

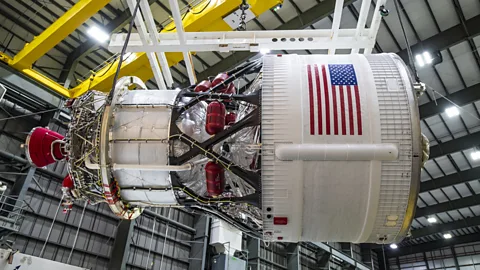

Now, Nasa hopes to send humans to the Moon using a rocket insulated with cork. Nasa's new heavy-lift rocket, the Space Launch System (SLS) accelerates from 0-17,400mph (0-28,000km/h) and soars to more than 100 miles (160km) above Earth in just eight minutes. As it flies, it builds up extraordinary heat. But the cryogenic fuel – made of liquid hydrogen and liquid oxygen – that powers the rocket must remain cold. If temperatures rise too high, the fuel becomes a gas

Alamy

AlamyThe third Artemis mission will see the SLS launch astronauts in Nasa's Orion spacecraft on the first ever mission to the Moon's South Pole. Without sufficient insulation, the rocket's structural integrity would be compromised – and those astronauts' lives would be at risk.

Michael Alldredge is a materials engineer at Nasa. His job is to select the materials that will go into the thermal protection systems applied to the Moon rocket hardware. These will be crucial to "maintain structural temperatures during the ascent and operation of the vehicle", he says.

He watched the launch of Artemis I in November 2022 and says it was hard to process that, after years of work, it was finally leaving the launchpad. But with Artemis II in November 2024, then Artemis III in 2025 the stakes will be much, much higher – when humans will be on board.

"Everybody's got to stay calm and cool because, you know, we're still on console, watching the rocket, watching the performance," he says. "But we'll be trying to hold back the giddiness that comes with watching this mammoth vehicle just rip off the pad – all that power and thrust and force. It's breathtaking."

Currently planned for 2025, the mission will be the first time humanity will set foot on the lunar surface in more than 50 years. Four astronauts will depart from the Kennedy Space Center in Florida, sitting on top of Nasa's SLS – the only rocket powerful enough to send Orion, its crew and their supplies to the Moon in a single launch.

The SLS will have to endure extreme temperatures as it flies from the Earth, ranging from -423F (-253C) to more than 200F (93C). To cope, Nasa is advancing state-of-the-art technology for thermal protection – a spray-on foam insulation, along with other traditional insulation materials including cork – which promise to protect it from both fire and ice.

Cork, although heavier than the foam, provides stronger protection. Sheets and blocks of cork will be applied to areas of the SLS that have high predicted heat loads, says Alldredge. Take the core stage engine section, where four RS-25 engines will produce almost nine million pounds (40 million newtons) of thrust during launch and ascent. Cork will be laid under the solid rocket boosters, on the fairings, and the areas where feed-lines run down the rocket to connect to other hardware.

United Launch Alliance

United Launch AlliancePrior to the flight, there will be one final test of the insulation – when all four RS-25 engines will be fired up, the foam and cork will be guarding the hardware "as hot and cold collide".

"Down at the base of the vehicle it gets very hot during ascent," says Alldredge. "You've got the engines burning, and you have a lot of heat coming off the engines and the solid rocket boosters on the sides. So, we needed a material that was strong enough to deal with the heat loads at the base of the vehicle, and one that would ablate."

During ablation, explains Alldredge, some of the material on the outside of the vehicle burns up, taking the heat with it, allowing the underlying vehicle structure to remain cool.

But is sustainability top of Nasa's agenda when it comes to choosing the materials for its rockets? Not in terms of environmental impact, says Alldredge, but in the sense of reliable, long-term availability.

"Sustainability is not necessarily something that we seek from the outset," he says. "We look for what materials would work. Which ones can we get? Which ones are readily available? Which will be hard or expensive to get in the future? When you've got systems as complex as we deal with, the more things you can hold constant, the better."

Nasa/Joel Kowsky

Nasa/Joel KowskyThe UK Space Agency (UKSA), on the other hand, says it is taking steps towards reducing its environmental impact, with plans to use recycled materials – including cork – to insulate their launcher propulsion systems.

"We are focusing on environmental as well as economical sustainability," says Mauro Augelli, launch systems lead and engineer at UKSA. "It's about respect for the for the planet, and respect for the resources."

However, he adds, natural materials – which he defines as materials with minimal processing such as cork – can be unpredictable.

You might also like:

"If you don't process them very much, you can have uncertainties about the behaviour," he says. "Plus, when you consider exploration or life support for astronauts, biomaterials can catch fire, they have permeability. These are not qualities you want to have, for example, if you are creating a Moon base."

UKSA are currently assessing the lifecycles of the materials they use. The preference, he says, should go to materials with a lower environmental impact for the overall lifecycle.

"It's a trade-off between the objectives of the mission and [sustainability]. When we talk about lifecycle assessments, natural materials are better than other materials," he says.

However, he adds, UKSA are also exploring materials such as polymers which, when recycled, can be combined with other materials for use in thermal protection.

For now, however, trees are not only going to continue being important for life here on Earth, some are also destined for the stars.

--

If you liked this story, sign up for The Essential List newsletter – a handpicked selection of features, videos and can't-miss news delivered to your inbox every Friday.